Development of Active Cathode Materials

Customized Cathode Materials for Innovative Energy Storage Systems

In the fast-moving world of energy and materials research, it is crucial to always be at the forefront of technological innovation. A key aspect of this is the development of high-performance, reliable and cost-effective cathode materials that meet the specific requirements of your projects. Whether you are working on the optimization of batteries for electric vehicles, the development of stationary energy storage systems or the improvement of fuel cells – tailor-made cathode materials are the way to successful and efficient research and production.

Why Customized Solutions for Cathode Material Development?

Materials for electrical energy storage are studied and optimized by development teams worldwide. To realize the full potential of your technologies, you need materials that are perfectly tailored to your needs. Every research project is unique, and so should be the materials you work with.

Specific Performance Requirements of the Cathode

Every application has different requirements for the cathode material – from portable devices to large storage systems. Tailor-made solutions ensure that your materials offer the desired electrochemical properties, service life and performance.

Optimizing Materials for Innovative Battery Applications

The world of energy storage technologies is evolving rapidly. Customized cathode materials allow you to test new ideas and concepts that may not be feasible with standard materials.

Save Costs and Resources

By precisely adapting the material properties to your requirements, you can increase the efficiency of your processes, which can lead to significant savings in material and production costs.

Our Proposition: Tailor-Made Cathode Materials from a Single Source

At IBUvolt, we understand that the development of cathode materials is a complex task that requires a deep understanding of the materials and their interactions. That is why we offer you comprehensive support – from the initial idea through to implementation.

Dr. Katja Kretschmer

Head of Laboratory Analytics, Chemist, Technische Universität Carolo-Wilhelmina zu Braunschweig & University of Technology, Sydney, ~10 years of professional experience as a researcher in the fields of chemical engineering, materials science and electrochemistry.

Consulting and Specification Definition for Customized Cathode Material

The first step in the development of customized cathode materials is a thorough analysis of your requirements. Our experienced team of engineers and scientists will work closely with you to define the exact specifications that your materials must meet. We take all relevant factors into account, such as:

Electrochemical performance: Specific capacity, energy and power density, charging and discharging behavior.

Service life: Cycle stability, capacity retention, degradation mechanisms.

Environmental requirements: Temperature resistance, moisture susceptibility, environmental sustainability.

Processing properties: Scalability, compatibility with existing production processes.

Cathode Material Development in the Laboratory

As soon as the specifications have been defined, the actual development work begins. In our technical laboratories, we use a variety of efficient processes to develop materials with the desired properties. This includes the following:

Synthesis and modification: We use various synthesis methods to optimize the chemical composition and structure of the cathode material. This includes the modification of existing materials and the development of completely new compositions.

Characterization: To ensure that the developed material has the desired properties, we carry out comprehensive material characterization. Our electrochemical laboratory is equipped with almost all characterization methods.

Testing and validation: The performance of the developed cathode materials is extensively tested in batteries to ensure that they meet the requirements of your application.

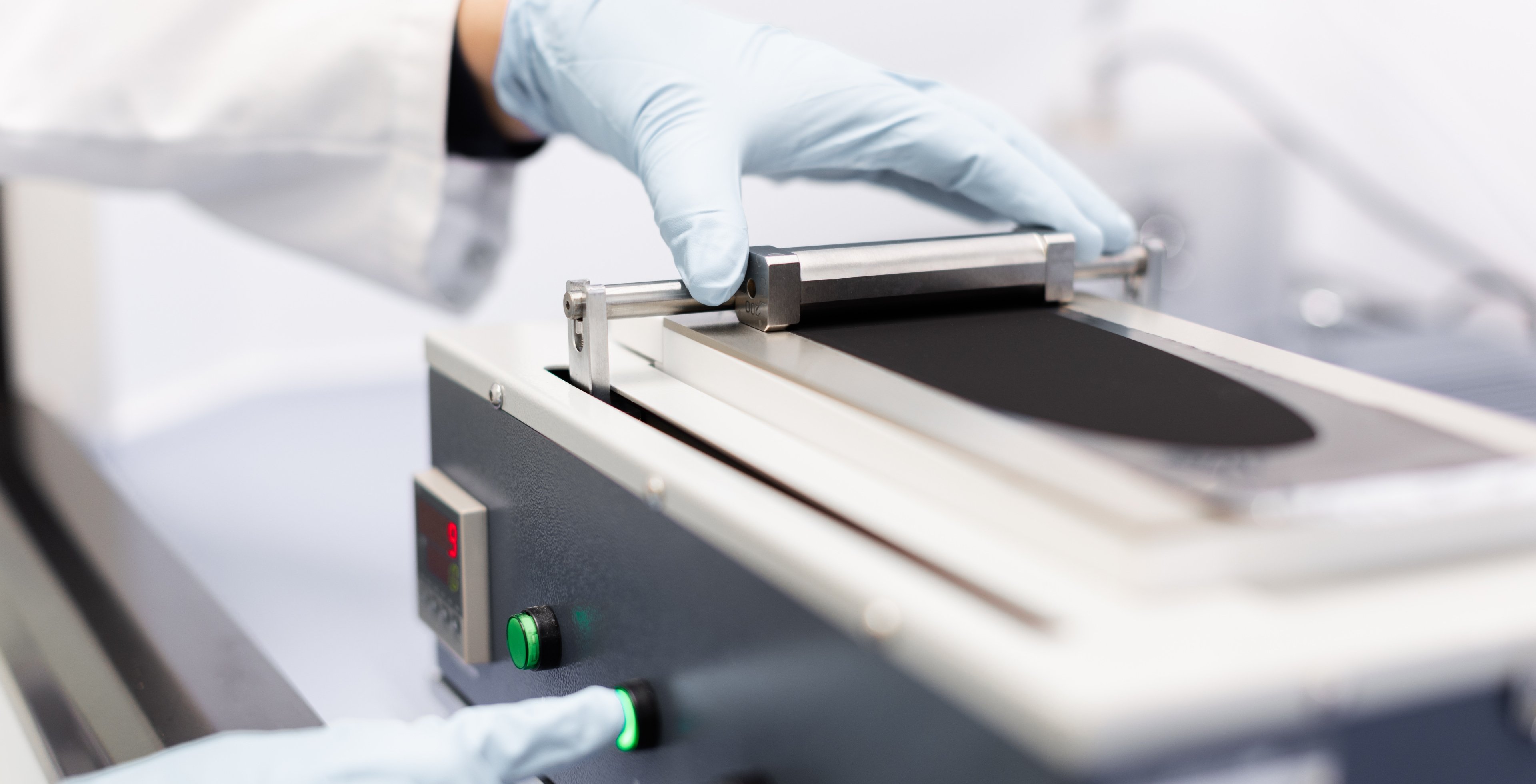

Scaling your Cathode Material in our Pilot Plant

The successful development of a cathode material in the laboratory is only the first step. In order to transfer your projects to production, we offer the option of scaling up material production in our pilot plant. Our pilot plants are designed to produce and test the materials developed in the laboratory under real production conditions. This ensures a seamless transfer of laboratory results to industrial scale.

Optimizing the process: Adjusting and fine-tuning the production process to maximize efficiency and quality.

Production of pilot quantities: Production of quantities of the developed cathode material in pilot production to validate the production process and prepare for industrial production.

Quality control: Comprehensive monitoring of material quality throughout the production process to ensure that all products meet the highest standards.

The IBUvolt Advantage

Individual solutions: Customized cathode materials that are precisely tailored to your specific requirements.

Support from experts: Our experienced teams will guide you through the entire process – from the initial idea in the laboratory to the market readiness of the material.

Proven technology: Our laboratories and pilot plants are equipped with proven technology to ensure that your materials are scalable and can be produced using industrially relevant methods.

Efficiency and sustainability: By optimizing materials and processes, we help you reduce costs and conserve resources, important for the overall balance of your battery materials.

The Key to Your Success

Developing customized cathode materials is a crucial step to succeed in the highly competitive world of energy and materials research. With our comprehensive service portfolio, we offer you the opportunity to implement your projects faster, more efficiently and more successfully. Put your trust in our expertise and our passion for innovation - together we will shape the future of energy storage!