NibLog – Sodium-Ion Batteries in Intralogistics

Prototype of a Polyanion-Based Sodium-Ion Battery for Forklifts

Lithium-ion batteries are currently the most widely used battery systems. Although they are characterized by their high energy density, this also leads to a high hazard potential due to flammability. In addition, the batteries should never be fully discharged in order to avoid damage. Another problem is the limited resources. The search for alternatives is becoming increasingly important as a result of rising demand with constantly limited and locally anchored reserves.

Sodium as an Alternative

According to forecasts, the world's lithium reserves will be exhausted in around 28 years. Sodium-ion batteries play a key role as an alternative! Thanks to the same functional principle, they allow rapid development as so-called “drop-in” technology. With global reserves up to 1000 times greater than those of lithium, dependencies in the raw material supply chains could be avoided.

The research project “Sodium-ion batteries for use in intralogistics: from scalable cathode active material production to prototype cells”, NIBlog for short in German, aims to use a prototype module developed in the project directly in forklifts. In addition to the IBU-tec R&D team, the project consortium consists of Frauenhofer IFAM, E-Lyte Innovations GmbH, Daikin Chemical Europe GmbH and Univercell Holding GmbH.

Development Along the Battery Material Value Chain

The project covers the entire value chain of battery production: It starts with the cathode active materials, which can be categorized as Berlin blue derivatives (often referred to as Prussian blue analogues, PBA, IFAM) and polyanionic compounds (PA, IBU-tec). Prussian blue analogues (PBA, IFAM) and polyanionic compounds (PA, IBU-tec). Suitable binder systems are selected for their processability in electrode production (Daikin). The electrolyte (E-Lyte) is crucial for achieving high cycle stability with a long battery service life. The material is then sent to Univercell for processing and cell production. In addition to the prototype production itself, the focus is also on the possibilities of establishing a European value chain. The aim is to reduce dependence on Asian supply chains and strengthen the local industry.

Current Project Status and Objectives

Our research focuses on the synthesis and development of cathode active materials, especially polyanionic compounds. With its high material stability, high cycling stability and a cell voltage that avoids electrolyte degradation, polyanionic compounds have promising properties for applications in sodium-ion batteries. The unique structural properties of sodium super conductors (NaSiCON) allow fast sodium diffusion and the resulting high charge and discharge rates of the battery. The broad raw material matrix also makes it possible to dispense with critical or harmful elements

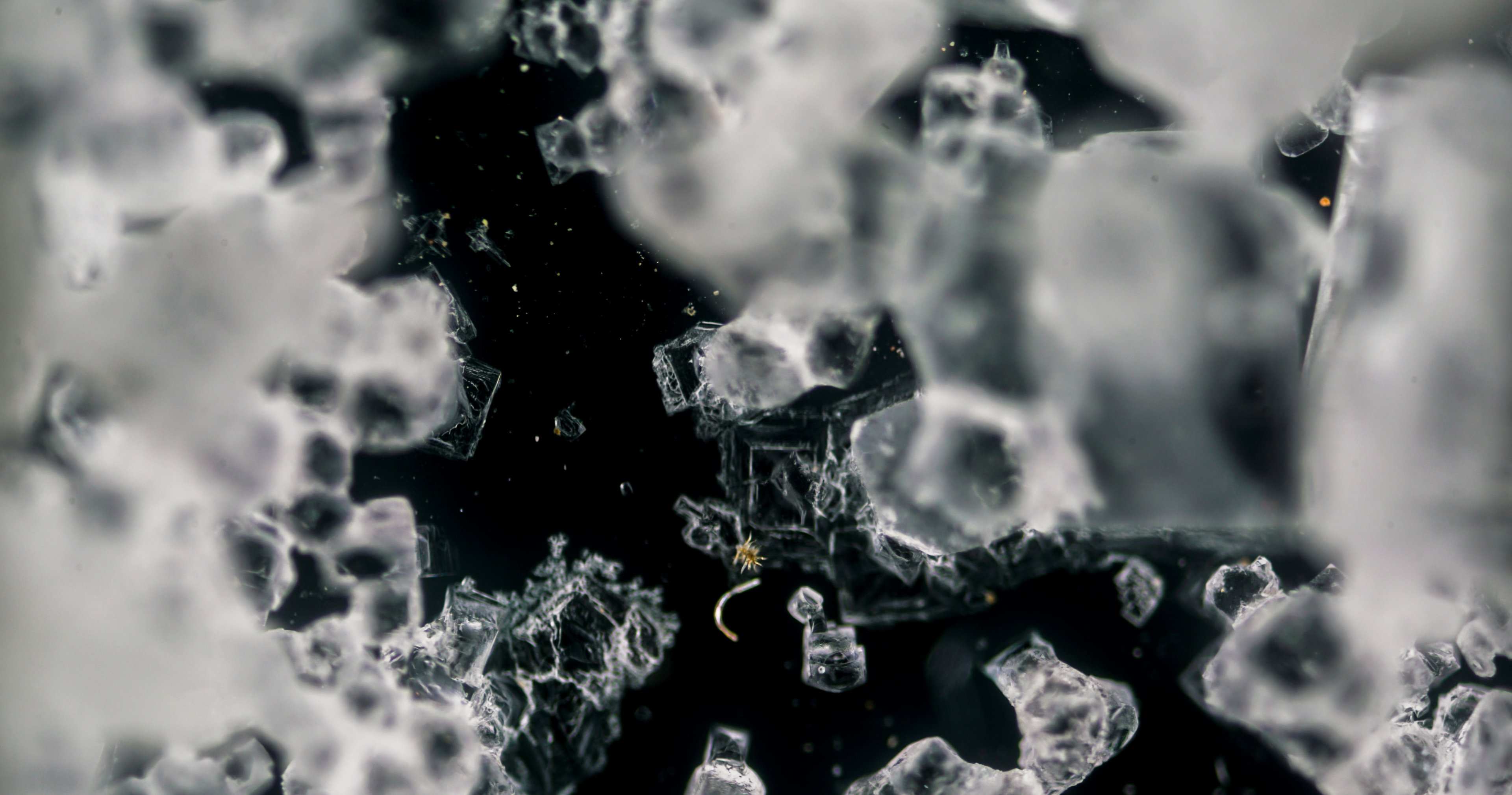

IBUvolt scientists have produced the first polyanionic compounds using a laboratory spray tower or the patented pulsation reactor technology and activated them electrochemically through thermal post-treatment. Using this production method, it has already been possible to generate materials that are almost phase-pure!

In cooperation with the project partners, the finished active materials were then tested for their suitability in full sodium cells. The next step will be further Optimization in order to improve electrochemical performance. In order to keep the effort to a minimum, Creative Quantum will carry out quantum chemistry-based calculations, which will allow a preselection to be made for the dopants, for example. If the experimental results obtained are satisfactory, the active materials synthesis is then scaled up in order to provide the project partners with sufficient material for processability and prototype production.